Autodesk Inventor

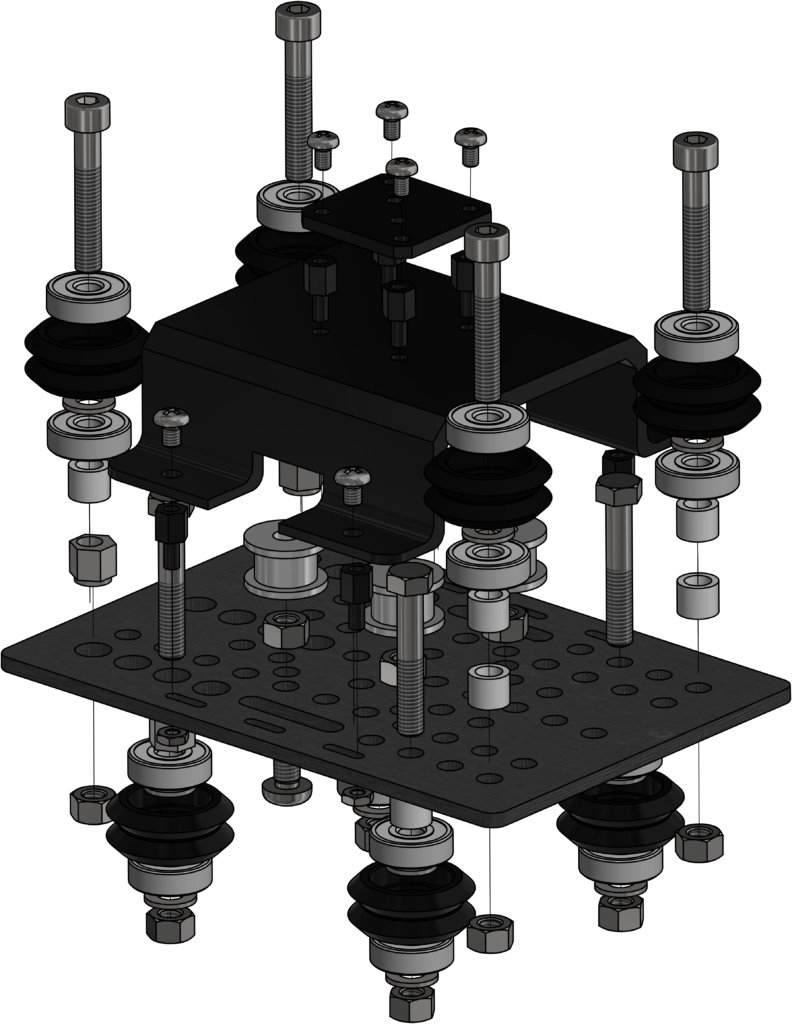

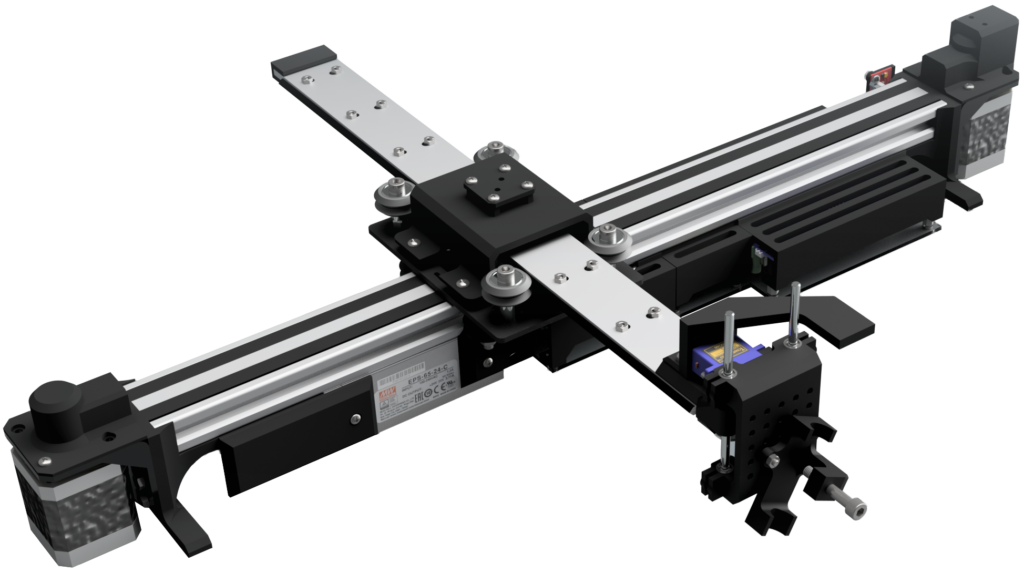

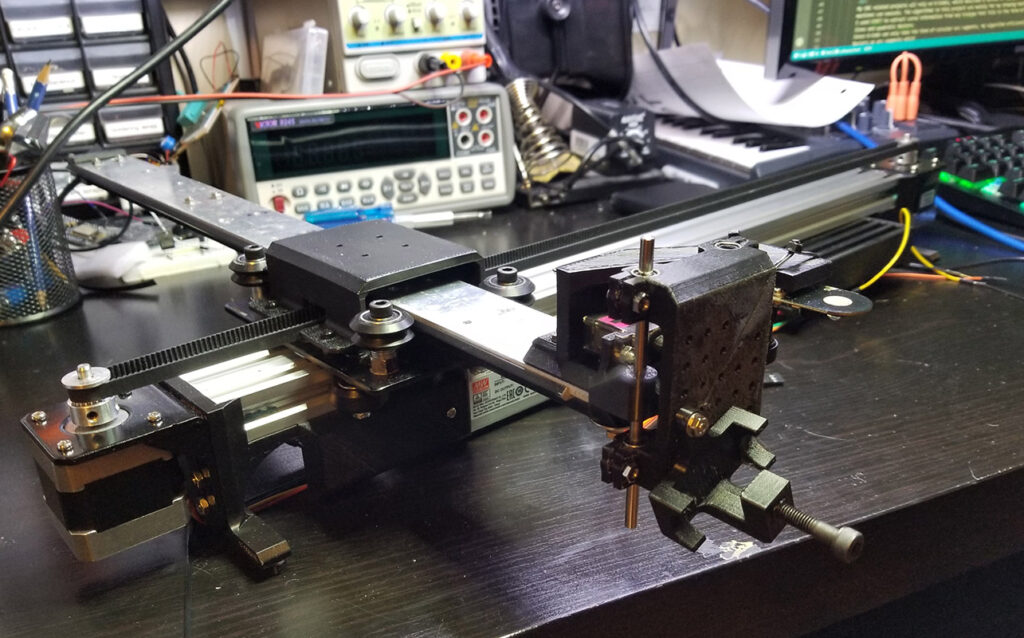

The hardware portion of my capstone project is a CoreXY CNC plotter inspired by the Axidraw V3 by Evil Mad Scientist Laboratories. When I created the design I used OpenBuilds components for the primary extrusion and the wheels. The secondary Axis uses an aluminum plate milled by hand which has been fastened to OpenBuilds rails. The rest of the device is made from 3D-printed parts.

See the software component of this project here

I assembled the entire machine in Autodesk Inventor and built it from both standard aluminum parts as well as many of my own parts 3D printed on my homemade delta printer. The machine is controlled over WIFI via a Raspberry Pi which forwards G-code commands to a modified Duet 3D printer controller which drives the motors. The Duet triggers the servo using its IO and a custom servo-driving PCB which has its own configurable settings.

Other than motor driver firmware and certain libraries, all software has been created from the ground up.

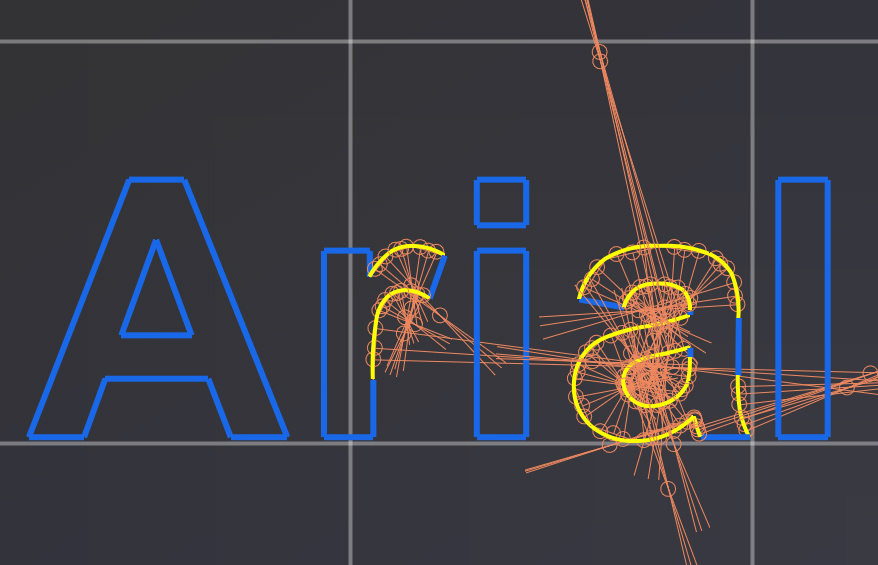

This includes generating all the G-Code using my G-Code Workbench software. The machine is equipped with a camera that can scan the printing surface.

Using OpenCV, the images are corrected with a custom lens distortion map and stitched together to form a single image. The robot is even capable of replicating the scanned drawing using the contour detection in OpenCV in combination with many of my own algorithms in G-Code Workbench.